Home

![]()

Contents

![]()

Company

Profile

![]()

Finishing

Systems

Burners

![]()

Cell

Washers ![]()

Railroad

Products

![]()

Residential

Products

![]()

Fabrication/

Welding

Bintzler

Incorporated

Natural

and Propane

Gas

Burners

![]()

|

Atmospheric mixer with Bintzler cage showing mounting, pilot mixer, and UV scanner |

Bintzler

Inc. Designs and manufactures immersion tanks for cleaning,

phosphating, rinsing, and stripping. Immersion units are generally

heated using atmospheric burners firing into a tube, or with steam

coils.

Immersion tubes are installed vertically in the tank, with a partial partition to cause circulation and agitation over the partition. Atmospheric burners offer a lower cost alternative to the blower type pressure burners. Some burner manufacturers are trying to get away from atmospheric units. Bintzler has had to begin assembling burners from component parts. The cage shown is manufactured by us to fill a void left by burner companies. This cage is available to replace existing units in the field when required. It is also available for incorporation into new assemblies. The cage is fabricated from steel, or stainless steel. Collars and pipe nipples for mounting pilot burners, flame rods, or UV scanners are included. These will not crack or break like units cast from aluminum. |

Drilled orifice pipe burners located under a phosphate tank |

In some situations, it is more advantageous to use burners shaped in a ring, or drilled orifice pipe burners. These units are designed to be placed under a tank. Units such as these are used when tank size does not allow room for a heating tube inside the tank either vertically against one side, or horizontally along the tank bottom. As shown, the pipe burners are positioned under a formed cavity in the tank bottom. This method gives the flame more surface area with which to heat the solution.

|

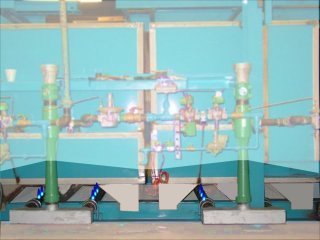

A simple safety valve train using On/Off burner control |

Bintzler Incorporated

designs complete assemblies. This includes the burner of the proper

capacity to compensate for heat losses in the solution. These can be

from spray losses, evaporative losses, or losses from the amount of

material passing through the system.

As well as the burner, the pilot, valve train, and safety equipment are all part of the working burner assembly. These burners can be set up in a variety of ways. One is to use an On/Off arrangement. When the temperature control call for heat, the main flame is burning. When not, only the pilot flame is lit. Another method is to use a High/Low fire arrangement. With this method, a third safety valve is used, with a by-pass around it for low fire. A third method is to modulate the burner flame. This uses a special temperature controller with a modulating motor operating a butterfly valve in the main gas line. |

Control Panel with IEC starters, PLC logic and Panelview operation |

Additionally, all of the above burner and safety valve train assemblies require controls. Bintzler Inc. designs control / wiring packages for every piece of equipment manufactured. Sometimes Programmable Logic Controls are required. PLC controls have an infinite number of relay and timer contacts. They can be programmed, and reprogrammed over and over. Most are expandable, with the ability to accept numerous changes and additions. When equipment is less complicated, simple timer/relay controls are usually sufficient, and less costly. Bintzler Inc. works with our customers to determine what their needs are, and the best way to fill those needs. |

"Our #1 goal is to best serve our customers."

| Home | Contents | Company Profile | Finishing Systems |

Burners | Cell

Washers | Railroad Products |

![]()

| Residential Products | Fabricating/Welding | Maintenance

| Material

Handling | |Consulting Service | Contact Us | Links |

8918 Glendale-Milford Road - Loveland, Ohio 45140