Home

![]()

Contents

![]()

Company

Profile

![]()

Finishing

Systems

Burners

![]()

Cell

Washers

![]()

Railroad

Products

![]()

Residential

Products

![]()

Fabrication/

Welding

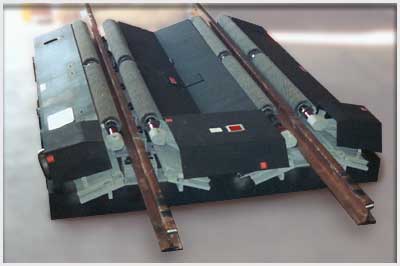

Railroad Products

Shown here is the Bintzler Incorporated Rail Wheel Cleaner, U. S. Pat.#5,991,952. The unit consists of four spiral wound brush assemblies driven by four 10hp motors. The brushes are activated when a signal is received from the control tower and wheel detector. An upper brush plate rolls forward on special rollers to move the brushes against the rail car wheels. Each brush is the length of the wheel's circumference. Cleaning takes place as the cars pass through the brushes. The sliding plate is pushed forward by a specially designed linkage powered either by air or electric actuators, whichever the customer prefers.

This equipment is intended for certification (hump) yards, installed ahead of the master retarder. The purpose is to remove contaminates which can hinder or even eliminate the effectiveness of the retarder braking.

Bintzler Incorporated has manufactured wheel cleaners for major freight railroads across the country, and has been contacted by some in Canada.

The unit is supplied complete, mounted on 7- 10" x 10" x 10' retarder ties, with 19'-6" of rail. 136# AREA rail is standard, however any size preferred by the customer can be used. Installation should not present any difficulties as the unit can be set in the line, connect the rail, either with bolting plates, or welding. Then connect power and air (if necessary).

Options which can also be supplied include: a basic control panel, a control panel with PLC and modems to communicate directly with the tower computer, and a Brush Adjustment Gage to maintain proper engagement for optimum cleaning and brush life. Permanently lubricated bearings can also be requested to reduce maintenance requirements.

| Home | Contents | Company Profile | Finishing Systems |

Burners | Cell

Washers | Railroad Products |

![]()

| Residential Products | Fabricating/Welding | Maintenance

| Material

Handling | |Consulting Service | Contact Us | Links |

8918 Glendale-Milford Road - Loveland, Ohio 45140